Biomass Gasifier

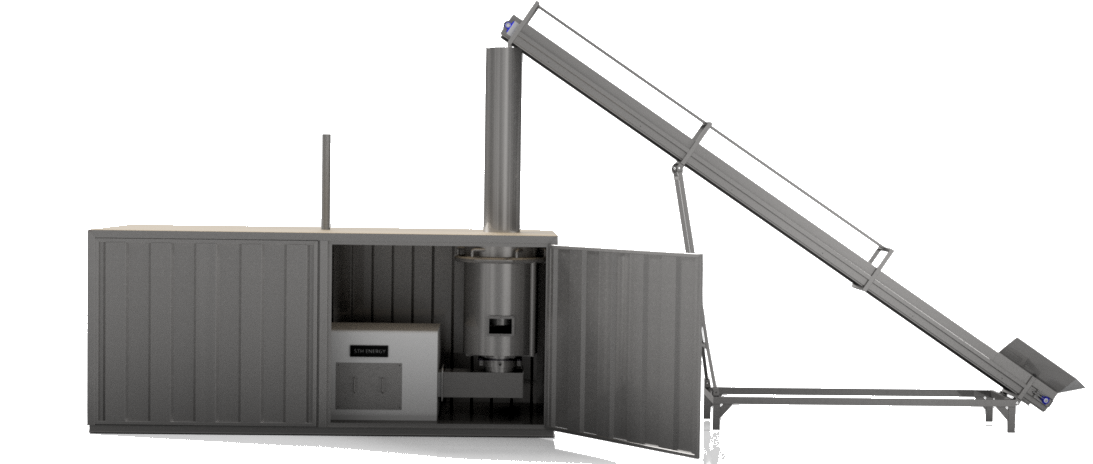

The Biomass Gasifier is P-GEM’s flagship product. Years of experience, research, design and development have gone into our Gasifier solutions.

P-GEM Gasifiers are designed and built around the specific need of the project. These tailor made solutions takes into account the specific application or combination of applications.

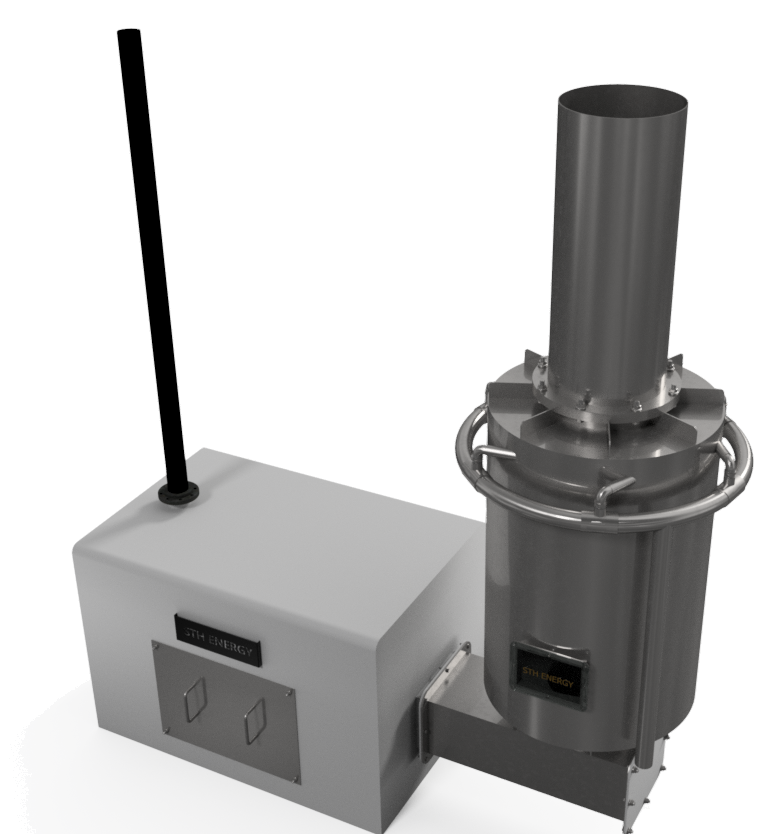

Our gasifiers get delivered with the following in mind unless the client specify differently.

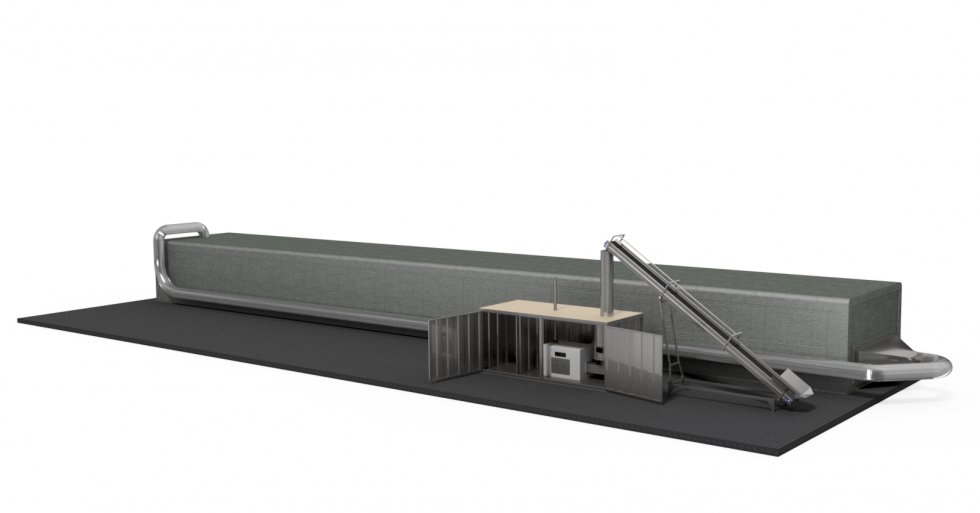

- Units are built into a compact unit within a container

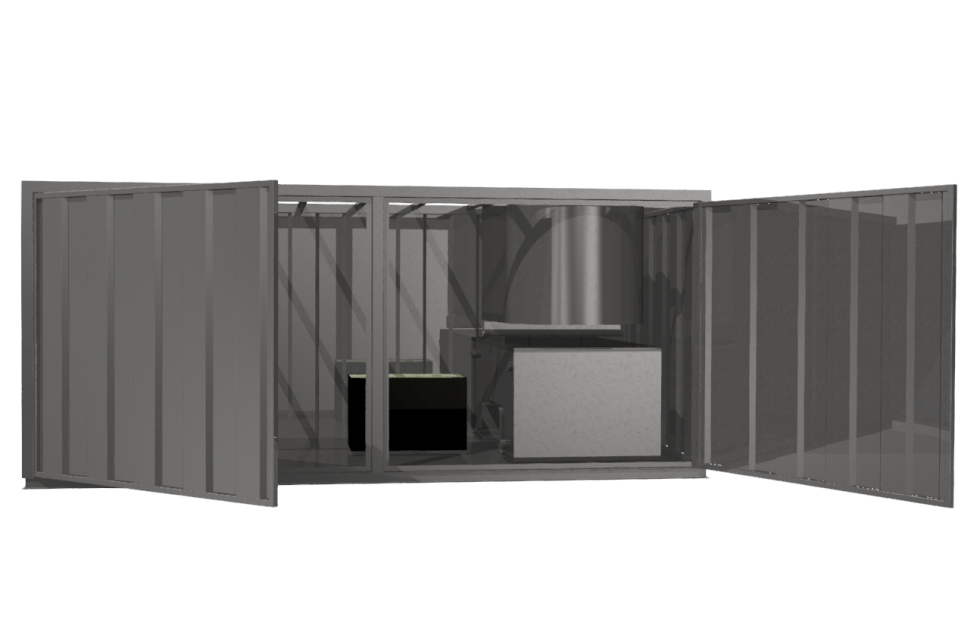

- All electronic, electric work is done and built into a separate room within the container

- Units are run and fully tested before they are being dispatched

- Minor assembly is required at the site

- Units are designed and built in a modular way to easily repair, replace and upgrade

- All units comes with a complete operating manual as well as training on use

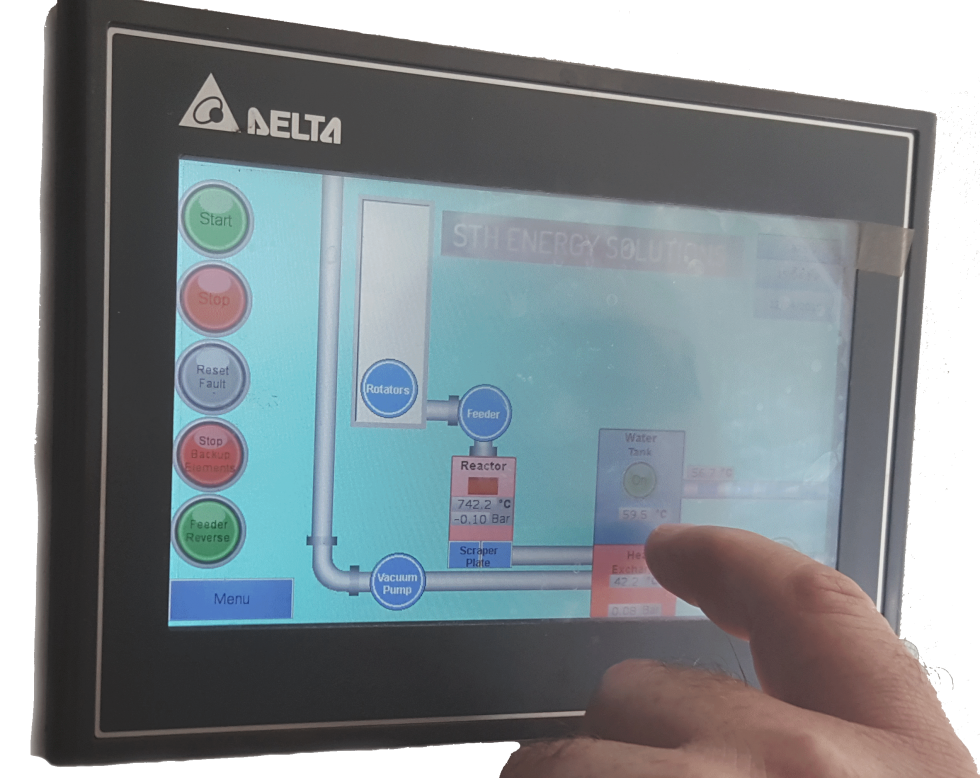

- Functionality, operation, cycles and other features can be set locally at the control interface for the unit, or can be done via remote terminal on a tablet, phone or PC