Biomass Gasification

Affordable Thermal Energy

Biomass Gasification is not a new concept. The proper implementation in industry today has however been set aside with the availability of easier grid resources at, until now an affordable price. To generate large amounts of heat either for curing, drying, steam applications or electricity applications has been left to the power suppliers.

Now that energy is becoming more and more expensive, while at the same time there is a harder push to rethink the ways we interact with the environment we find that alternative solutions must be developed for companies to generate their own energy and become more self-reliant.

A gasifier is essentially a chemical reactor that uses wood chips, charcoal, coal or similar carbonaceous materials as fuel and burns them in a process of incomplete combustion due to a limited air supply.

The Process

Gasification is a process based on pyrolysis at high temperatures (>800°C) and in general long residence time of the hot vapour in the system. This generates – as a main component – a combustible gas.

Gasification is basically a process where biomass material such as wood chips gets burned at high temperatures in excess of 800°C. The oxygen flow is regulated and reduce to prevent the full combustion of the material which then forms a highly combustible gas called Syngas or Synthetic Gas.

Syngas consists mainly of a mixture of Carbon Monoxide (CO) and Hydrogen (H). This gas is in return the raw source of energy (Fuel) used for various purposes.

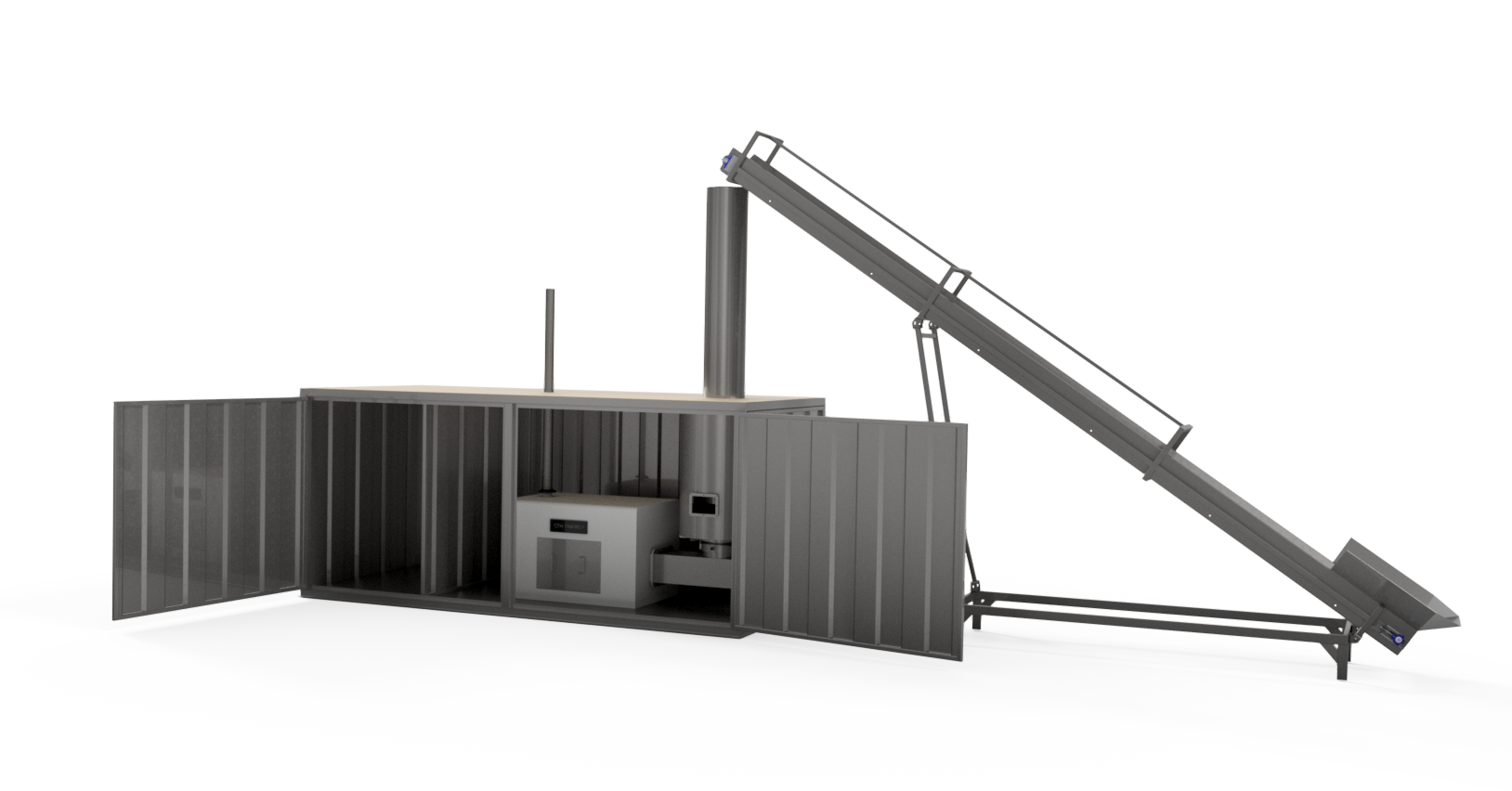

The Gasifier

There are many different gasification methods in use or in development, but the downdraft fixed-bed technology is almost exclusively used for small-scale power gasifiers. This is the only economic option on a small-scale that also produces a fairly clean gas.

These gasifiers are usually manufactured as a batch unit or a constant feed unit. This would depend on the cycle that the gasifier is required to run.

The advent of technology such as PLC’s (Programmable Logic Controllers), VFD’s (Variable Frequency Drives) and many more has started to make these units more and more efficient and durable.